|

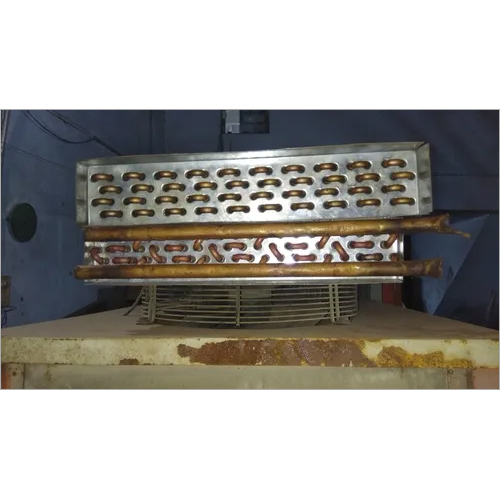

Shell and Tube Condenser

Shell and Tube Condenser Specification

- Material

- Copper tubes, Mild steel shell

- Type

- Shell and Tube

- Style

- Horizontal

- Refrigerant

- R22, R134a, R407C

- Climate Type

- Tropical

- Temperature

- Up to 120C

- Power

- 0.75 kW to 11 kW

- Voltage

- 220V/380V

- Capacity

- 5 Ton to 250 Ton

- Layer

- Single/Double Layer

- Cooling Method

- Water cooled

- Maintenance

- Easy access for cleaning

- Tube Thickness

- 0.56 mm to 1.2 mm

- Test Pressure

- 1.5 times the working pressure

- Corrosion Protection

- Epoxy painted shell

- Number of Tubes

- 20 to 300

- Connection Size

- Customized as per requirement

- Tube Diameter

- 12.7 mm to 25.4 mm

- Installation

- Floor mounted

- Application

- Industrial HVAC, Refrigeration, Chemical plants

- Design Pressure

- Up to 25 bar

Shell and Tube Condenser Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 2 Week

- Packaging Details

- Wooden Box Packaging.

- Certifications

- MSME Certifications.

About Shell and Tube Condenser

In order to fulfill the demands of our esteemed clients, we are engaged in providing an optimum quality array of Shell and Tube Condenser. This condenser is widely used in pharmaceutical, chemical, beverage and paper industries. The offered condenser is manufactured using optimum quality components as per industry standards with the aid of ultra-modern techniques by our ingenious professionals. Apart from this, our clients can avail the offered Shell and Tube Condenser at most competitive prices from us.

Key Points:

- Trouble free operation

- High corrosion resistance

- Longer operational life

- Efficient performance

Robust Industrial Performance

Our shell and tube condenser, featuring high-quality copper tubes and mild steel shell, delivers reliable cooling in challenging environments like chemical plants and industrial HVAC systems. The epoxy-painted shell ensures long-term corrosion protection, making these units suitable for tropical climates and heavy-duty cycles. Its horizontal style, single or double-layer design, and customized connections offer adaptability for a wide range of installations.

Efficient Maintenance and Longevity

Engineered for easy access, our condensers simplify routine cleaning and maintenance, ensuring continued peak performance. With a test pressure rated 1.5 times the working pressure and epoxy-coated surfaces, operators enjoy a lower risk of downtime and reduced long-term operational costs. Floor-mounted installation supports a stable base, while a capacity range up to 250 tons meets most industrial cooling needs.

FAQs of Shell and Tube Condenser:

Q: How does a shell and tube condenser work in industrial applications?

A: A shell and tube condenser transfers heat from hot refrigerant gases inside the copper tubes to cooling water circulating around the tubes within the mild steel shell. This cooling process condenses the refrigerant back into a liquid state, making it ideal for industrial HVAC, refrigeration, and chemical processing applications.Q: What are the benefits of using epoxy painted shells in these condensers?

A: Epoxy painting the mild steel shell provides superior corrosion resistance, ensuring durability and a longer operational life, especially in harsh, humid, or tropical environments where conventional shells may corrode quickly.Q: When should maintenance or cleaning be performed on shell and tube condensers?

A: Regular maintenance is recommended based on operational hours and water quality, with periodic cleaning at least once or twice a year. The condensers easy-access design allows for efficient cleaning of internal tubes and shell surfaces to maintain optimal heat exchange.Q: Where can these condensers be installed and used?

A: These condensers are floor mounted and suitable for various industrial settings including chemical plants, large-scale refrigeration systems, and HVAC projects. Their customizable connection sizes ensure compatibility with different installation environments.Q: What is the process for ensuring safe operation at high pressures?

A: Each condenser is hydrostatically tested at 1.5 times its maximum working pressure before commissioning to ensure safety and integrity during operation under pressures up to 25 bar.Q: Which refrigerants are compatible with this condenser?

A: This shell and tube condenser is compatible with multiple industrial refrigerants such as R22, R134a, and R407C, offering flexibility for diverse cooling system requirements.Q: What usage advantages does the condensers design provide?

A: Featuring a range of tube diameters, thicknesses, and customizable tube numbers, the design allows for tailored performance to match specific cooling loads. Its robust construction and user-friendly maintenance features support continuous, reliable operations in demanding industrial contexts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensing Unit Category

Air Cooled Condenser

Minimum Order Quantity : 1 Piece

Temperature : 10C to 55C

Voltage : 220V / 380V

Layer : Single / Double

Style : Other, Horizontal / Vertical

Refrigerant : R22, R134a, R404A, R407C

Condensing Unit

Minimum Order Quantity : 1 Unit

Temperature : 20C to +10C

Voltage : 220V

Layer : Single

Style : Other, Industrial

Refrigerant : R404A

|

S.M. CHILLERS INDIA PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |